Description

Classification: chemical engineering industry

Case overview: Based on many years of actual production experience and existing production technology, combined with the current national pharmaceutical industry GMP standard requirements, Haomai drying has produced a GMP oven with reasonable structure and excellent hot air circulation effect.

Hot air circulation drying oven is a universal drying equipment with a long history. It has a wide range of applications, uniform temperature, high thermal efficiency and simple operation. It is one of the necessary drying equipment for most pharmaceutical and related enterprises, and it is also a popular drying equipment. Based on many years of practical production experience and existing production technology, combined with the current GMP standard requirements of the national pharmaceutical industry, Haomai drying has produced a GMP oven with reasonable structure and excellent hot air circulation effect.

Product Description:

There are three kinds of heating heat sources: steam, electricity and steam.

Service temperature: steam heating 50-140 ℃, high 150 ℃; electric heating 50-350 ℃;

The temperature is controlled automatically and recorded by recorder;

The inner wall of the box is fully welded, and the arc transition is adopted at each transition without dead angle.

The whole machine has good sealing performance, and the unique guide rail sealing device ensures the sealing performance of the whole machine;

The air inlet is equipped with high-efficiency air filter; the moisture outlet is equipped with medium efficiency air filter.

Double door oven double door to realize mechanical interlock;

All parts in the oven can be quickly disassembled and installed to facilitate cleaning;

The control system is equipped with text display and touch screen for selection;

The whole machine meets the requirements of GMP.

Technical features:

1. Equipment material: SUS304 stainless steel inside and outside, inner wall: δ = 2mm. The outer wall is made with δ = 1.5mm, so that the outer surface of the box is flat, smooth, and the color is consistent. The overall appearance is beautiful, and there is no obvious concave convex phenomenon;

2. Drying car production: the column is made of stainless steel square tube, and the beam is made of stainless steel angle steel, which is welded by argon arc welding. The wheels are made of high temperature resistant nylon wheels. Each drying car is equipped with two directional wheels and two steering wheels. The overall structure of the drying car is reasonable, strong, beautiful and practical.

3. The heating mode of the oven is: Electrical dual-purpose, and the electric heating tube is made of stainless steel tube and aluminum fin. Its heating effect is good, sanitary conditions are good, and to meet the requirements of anti riot. It can ensure that the temperature difference between the upper and lower parts of the box is ± 2 ℃.

4. The large air volume and low noise axial flow fan is used as the circulating fan in the oven, and adjustable air distribution devices are set on the left and right sides of the oven. In this way, the forced ventilation makes the air volume uniform and the wind speed large, and ensures the material drying quickly and evenly.

5. The inlet air of the oven is equipped with a sub high efficiency filter to ensure the cleanliness of the circulating air in the oven; the medium efficiency filter is equipped for the outlet air and moisture exhaust to ensure the cleanliness of the return air.

6. The oven door lock adopts advanced adjustable elastic lock, which has good locking performance and easy operation. High temperature resistant and non-toxic silicone rubber sealing ring is used between the door and the box body, with excellent sealing performance. The insulation layer of the oven is made of rock wool, which has good heat preservation performance.

7. The oven control cabinet is a touch type control cabinet with digital display function and sensitive action. Automatic controller is used to keep the temperature in the oven constant at the set value, and sound and light alarm is provided after exceeding the limit. (the temperature is controlled by the upper limit. If the temperature exceeds the upper limit of protection, the heating will be forced off and the sound and light alarm will be given at the same time.)

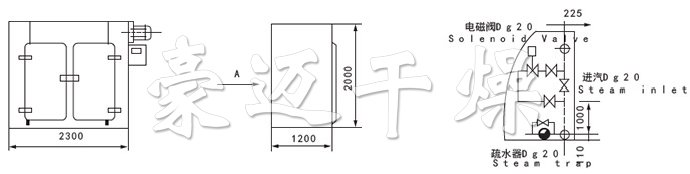

Installation diagram:

Technical specifications:

|

Model and specification |

Drying quantity per time(kg) |

Fan power(kw) |

Steam consumption(kg/h) |

Drying car (set)(set) |

Baking dish(只) |

Width × depth × height (mm) |

Upper and lower temperature(℃) |

|

GMP-O |

35 |

0.45 |

8 |

/ |

16 |

1130×1100×1750 |

±2 |

|

GMP-I |

120 |

0.45 |

18 |

2 |

48 |

2300×1200×2000 |

±2 |

|

GMP-II |

240 |

0.9 |

36 |

4 |

96 |

2300×2200×2000 |

±2 |

|

GMP-III |

360 |

1.35 |

54 |

6 |

144 |

3430×2200×2000 |

±2 |

|

GMP-IV |

480 |

1.8 |

72 |

8 |

192 |

4460×2200×2290 |

±2 |

Most of the hot air circulates in the box, with high thermal efficiency and energy saving. With the function of forced ventilation, the box is equipped with an adjustable air distributor, so the materials can be dried evenly, and the heat sources can be steam, hot water, electricity and far-infrared. The noise of the whole machine is small and the operation is balanced. Automatic temperature control, convenient installation and maintenance. It can be used for drying various materials. It is a general drying equipment.