Description

Key words: gelatin dryer, gelatin belt dryer, edible gelatin dryer, gelatin drying, gelatin drying, gelatin special dryer

Classification: Food Engineering Industry

Case summary: the gelatin before drying is a continuous sheet with strong viscosity. During drying, it will shrink due to the change of temperature. It is necessary to control the material to be heated evenly during the operation. It is recommended to use the heating method of hot air injection to treat the products.

Online consultation

1、 Process conditions:

1. Material name: flake edible gelatin

2. Treatment capacity: 20t / month

3. Heating mode: electric heating

4. Power requirements: voltage: 380V 3-phase 50 Hz

2、 Material analysis

the gelatin before drying is continuous flake with strong viscosity. During drying, it will shrink due to the change of temperature. It is necessary to control the material to be heated evenly during the operation. It is recommended to use the heating method of hot air injection to treat the products.

3、 Drying process description

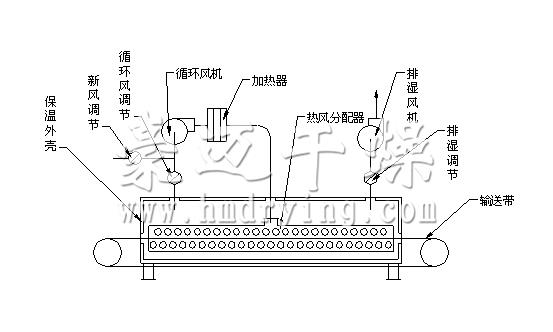

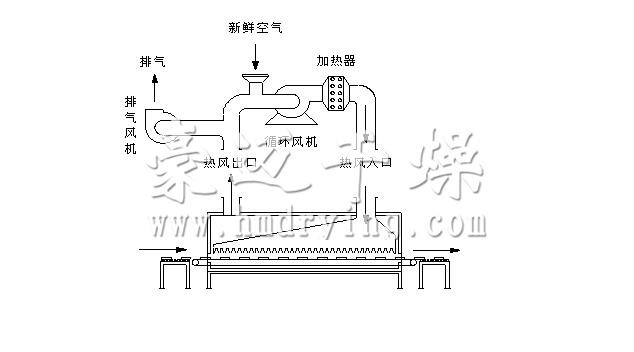

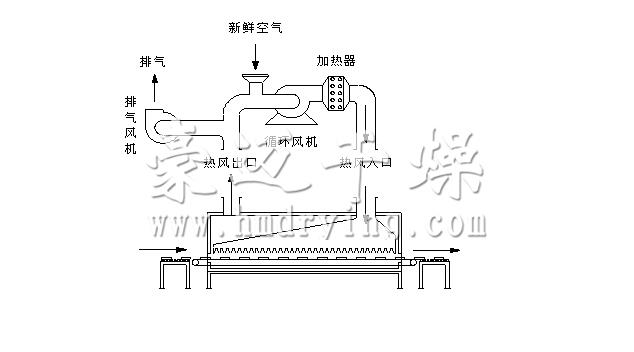

DWP type belongs to jet airflow belt drying, the principle is shown in the figure. In this type of equipment, the hot air flows down or up and down at the same time to the materials on the conveyor belt in the form of slit flow or hole bundle. As the jet gas velocity is higher than 15m / s, the convective heat transfer film is extremely thin, the heat transfer coefficient is large, and the drying speed is fast. This type of equipment is used to inject hot air up and down at the same time when airtight materials are used, and then participate in the circulation through the fan. It has strong penetrability and diffusibility in the material. This type of equipment is mainly used for fiberboard, gypsum board, carton board, pulp mold, coating drying, etc. it is also suitable for drying sheet, strip, granular materials and some special materials. If two-way air jet is used, the deformation of plate materials is small, and other types of materials are heated evenly, so it is not easy to produce sandwich state. The jet airflow belt type can use steam, electricity, coal-fired hot blast stove and fuel gas ventilation as the heat source.

Principle of unidirectional jet flow

Classification: Food Engineering Industry

Case summary: the gelatin before drying is a continuous sheet with strong viscosity. During drying, it will shrink due to the change of temperature. It is necessary to control the material to be heated evenly during the operation. It is recommended to use the heating method of hot air injection to treat the products.

Online consultation

1、 Process conditions:

1. Material name: flake edible gelatin

2. Treatment capacity: 20t / month

3. Heating mode: electric heating

4. Power requirements: voltage: 380V 3-phase 50 Hz

2、 Material analysis

the gelatin before drying is continuous flake with strong viscosity. During drying, it will shrink due to the change of temperature. It is necessary to control the material to be heated evenly during the operation. It is recommended to use the heating method of hot air injection to treat the products.

3、 Drying process description

DWP type belongs to jet airflow belt drying, the principle is shown in the figure. In this type of equipment, the hot air flows down or up and down at the same time to the materials on the conveyor belt in the form of slit flow or hole bundle. As the jet gas velocity is higher than 15m / s, the convective heat transfer film is extremely thin, the heat transfer coefficient is large, and the drying speed is fast. This type of equipment is used to inject hot air up and down at the same time when airtight materials are used, and then participate in the circulation through the fan. It has strong penetrability and diffusibility in the material. This type of equipment is mainly used for fiberboard, gypsum board, carton board, pulp mold, coating drying, etc. it is also suitable for drying sheet, strip, granular materials and some special materials. If two-way air jet is used, the deformation of plate materials is small, and other types of materials are heated evenly, so it is not easy to produce sandwich state. The jet airflow belt type can use steam, electricity, coal-fired hot blast stove and fuel gas ventilation as the heat source.

Principle of unidirectional jet flow

Principle of bidirectional jet flow