A new type of paddle sludge dryer

Based on the original hollow paddle dryer, our company has developed a new type of paddle dryer for sludge drying. The application results show that the product quality after drying meets the requirements of users. This new type of paddle dryer is an ideal sludge drying equipment at present.Sludge disposal has become an urgent problem in most wastewater treatment plants. The reduction, recycling and harmlessness of sewage sludge has become a major environmental protection problem that cannot be solved. Sludge drying is an intermediate link in the final disposal of sludge. After drying, the sludge can obtain low calorific value which reaches the natural combustion level and reaches a certain level of hygienic harmlessness, which provides conditions for the subsequent disposal of sludge.

Sludge thermal drying has the following advantages:

It can effectively remove bacteria and pathogens, and disinfect the end products to make them fully meet the relevant standards of sludge treatment and utilization;

It can greatly reduce the volume and weight of sludge, maintain the nutrients of sludge and make it recycled;

The treated sludge can be processed into some useful substances, such as biological fertilizer, soil remediation agent and fuel, etc., so as to obtain certain economic benefits.

Through comprehensive analysis of the structure and performance characteristics of various drying equipment at home and abroad, we found that the structure principle and drying process of hollow paddle dryer meet the current domestic sludge drying process requirements. Based on the original hollow paddle dryer, our company has developed a new type of paddle dryer for sludge drying. The application results show that this new type of paddle dryer is an ideal sludge drying equipment at present.

Optimization design of new paddle dryer for sludge drying

Improved design of condensate drainage system inside propeller blade shaft

According to the characteristics of sludge dewatering, the condensate drainage system inside the impeller shaft is improved. In addition, a device is added inside the blade to increase the drainage time in the process of blade accumulation and rotation, and the condensate drainage pipe is increased to increase the condensate water discharge, improve the suction pipe structure, make the condensate discharge more thorough and increase the output.

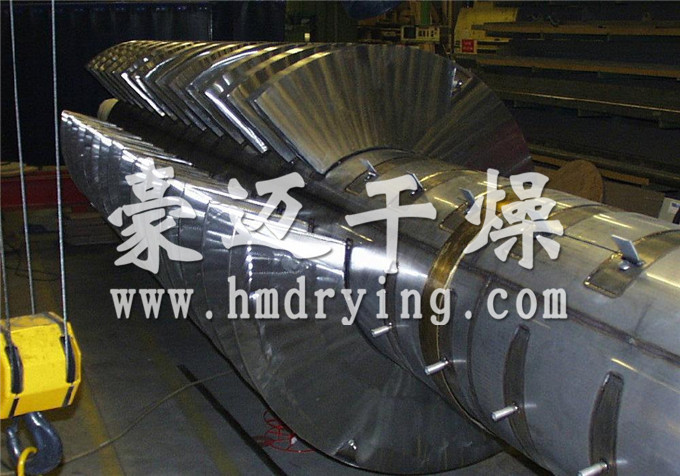

Modification of blade external structure

According to the characteristics of high viscosity and poor fluidity of sludge, in order to make the material flow forward, as when the blade dryer is installed, the equipment as a whole has a certain inclination to the direction of the outlet, but when the equipment is tilted, the flow speed of the material can not be well controlled, so it is difficult to control the material drying moisture. In order to improve the fluidity of sludge in the paddle dryer, some changes have been made to the external structure of the paddle, so that the blade can push forward the material. Changing the rotating speed of blade shaft can control the material pushing speed, make the material have a reasonable pushing speed, keep the material have a reasonable material level in the equipment, make the material fully contact with the blade surface, and further improve the heat transfer area.

Some devices are added inside the cylinder

When the moisture content is about 60%, the sludge is very easy to agglomerate, the surface is hard and hard to break, but the inside is still slime, which brings great difficulties to the further drying of the sludge; on the other hand, in the process of drying sludge, the sludge is easy to "hold the shaft", so that the blade and shaft heat dissipation are surrounded and move together when rotating. In order to overcome this difficulty, we have improved the paddle dryer by adding some devices inside the cylinder so that the agglomerated sludge is easy to be broken and the drying speed is greatly increased.

Working principle of new paddle sludge dryer

Paddle type sludge dryer is a kind of horizontal stirring continuous drying equipment. The dryer uses steam, hot water or heat transfer oil as heating medium, and the shaft end is equipped with a rotary joint for hot medium introduction and export. The heating medium is divided into two channels, which enter into the jacket of the drying shell and the inner cavity of the propeller blade shaft respectively to heat the body and blade shaft at the same time, and heat and dry the sludge in the way of conduction heating. The dried sludge is sent to the feeding port of the dryer quantitatively and continuously by the sludge pump. The sludge enters the back of the dryer, and the sludge is turned and stirred by the rotation of the paddle blade. The heating interface is constantly updated and contacted with the device body and paddle blades. It is fully heated to evaporate the surface water contained in the sludge. At the same time, the sludge is transported to the outlet in a spiral track with the rotation of the blade shaft, and the stirring is continued during the transportation, so that the water seeping from the sludge continues to evaporate. ^After that, the qualified products dried evenly are discharged from the outlet.

Characteristics of new type paddle sludge dryer

1. The equipment has compact structure, large heat transfer surface per unit volume and small floor area.

2. High heat utilization rate. The paddle type sludge dryer is heated by conduction heating, and there is no hot air to take away the heat, and the heat utilization rate can reach more than 90%.

3. The wedge-shaped blade has self-cleaning ability, which compresses and expands the material during rotation, which enhances the heat transfer effect.

4. The gas flow rate in the dryer is low, and the dust carried by the gas is less. The gas dust recovery of the system after drying is convenient, and the scale of tail gas treatment device can be reduced to save equipment investment.

5. The paddle dryer uses steam as the heat source, and it works with the garbage incineration power generation equipment. With the concept of circular economy, it can greatly save resources and reduce energy consumption.

Production effect of new paddle sludge dryer

The new paddle type sludge dryer is used in the sludge drying unit, and the dewatering capacity is basically more than 12kg / h ·m2. After drying, the moisture content of the sludge is reduced from 80% to less than 30%. The drying effect is good, and the product quality after drying meets the user's requirements. After drying, the sludge still has a calorific value of 1700-2500kcal, which can be mixed with coal and other conventional solid fuels, fully reflecting the principles of energy saving and circular economy. According to the different sludge, the structure is specially designed to ensure that the energy consumption of sludge drying is low. Indirect heat transfer such as conduction and radiation is used to dry the sludge