Sign the bill! The YPG800 pressure spray dryer is signed with Yunnan customers.

A company in Yunnan has sent materials to our company for testing. It is very satisfied with the materials we sent back. After a comparison among several manufacturers, we finally concluded a cooperation with our company to sign a YPG800 type pressure spray dryer.A company in Yunnan has sent materials to our company for trial. It is very satisfied with the materials we sent back. After a number of manufacturers' investigation and comparison, it concluded with our company to conclude a YPG800 type pressure spray dryer. The company is a high-tech enterprise, which is mainly dedicated to providing circular economy solutions and new building materials development and application promotion.

Design process:

Water evaporation capacity: 800kgh2o / h

Initial moisture content: 60%

Final moisture after drying: 10%

Yield: 1200kg / h

Inlet air temperature: 145 ℃

Exhaust temperature: 75 ℃

Selection equipment: YPG800 type pressure spray dryer.

Drying tower: diameter: Φ 5800 mm, height of straight cylinder: 23200 mm, total height of main tower: 35200 mm. Material: the inner wall material is 3mmssus316l, the insulation is 75mm rock wool, the outer seal is 1mm carbon steel, the tower and pipeline insulation outer wall are fully welded, polished and matted, the drying tower cylinder and the steel structure reinforcing ring bear the load, the bearing ring thickness is 20 mm, the material is carbon steel, the tower body reinforcement rib is angle iron, the material is carbon steel.

YPG800 pressure spray dryer specially designed:

1. Special design for granulation

we collect large particles at the bottom of the main tower, and the powder materials are pumped to the cyclone separator by the induced draft fan from the other outlet for gas-solid separation. After the powder is separated from the bottom of the cyclone separator to the pneumatic conveying pipe, roots blower is used to pump the powder to the top of the main tower. The powder spray nozzle is installed on the top of the pneumatic conveying pipe to spray the powder into the atomization area of the main tower, and the dry powder is equal to the atomized half The dry wet spherical powder adsorbs with each other to form large granular materials, which are discharged from the bottom of the main tower.

2. Special design for uneven atomization in tower

uneven atomization: due to the unreasonable design of the air guide system, the atomization is uneven, and there are wet materials mixed in the dried materials, resulting in unqualified products.

in order to solve the problem of uneven atomization in the tower, our company has made a long-term exploration and has completely solved this problem. Mainly through two aspects to solve. First of all, according to the design of hot air distributor to improve the distribution of hot air, three-layer mesh plate, each plate has different opening direction and opening rate, so that the hot air is more uniform. Secondly, the primary cooling air system is added to avoid the wet droplets sticking to the wall after atomization.

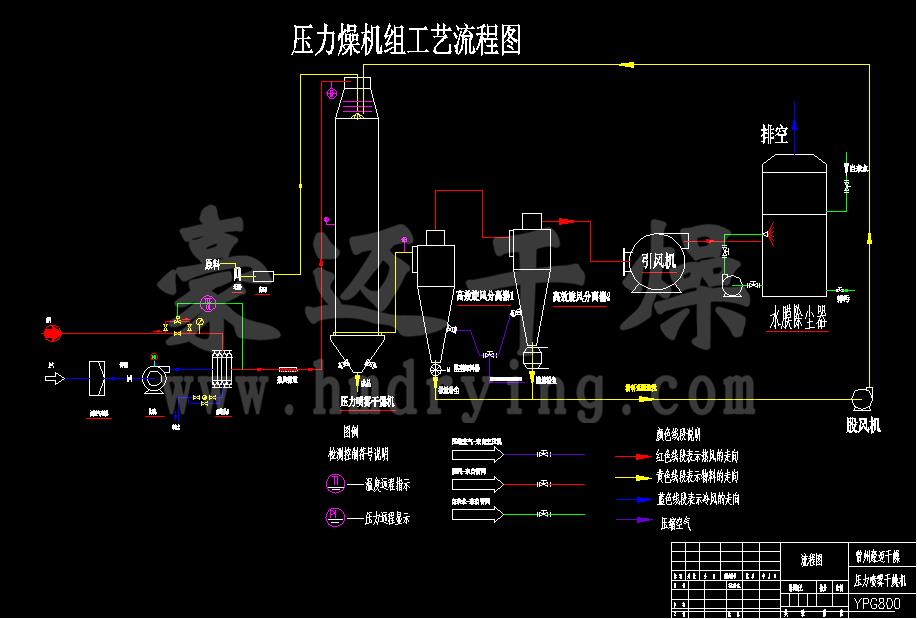

Flow chart of pressure spray dryer:

Changzhou Haomai drying Engineering Co., Ltd. has excellent quality, advanced technology and high practicability. It manufactures drying equipment, mixing equipment, crushing equipment, granulating equipment and screening equipment in good faith. With excellent quality and excellent service, we sincerely look forward to cooperating with domestic and foreign enterprises and providing customers with relevant technical support.