Application of spray drying in zero waste water discharge system

Spray dryer is a continuous method for drying solution, slurry and slurry in the shortest possible time. Since the liquid is atomized into a small droplet in the chamber through which the electric current passing through the hot air, the drying is fast.crystal

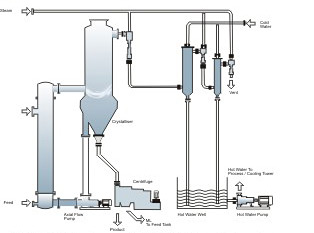

Crystallization of sodium chloride / unhydrous sodium sulfate

The concentration of solute separated from crystals during evaporation, solute increase and hybridization. However, since other salts are also precipitated depending on solubility, the purity of the main salt is not high, so it can be reused.

Crystallization of mirabilite (na2so4.10 H2O)

If the main part of salt effluent is sodium sulfate, it is recycled as mirabilite salt. The liquid is concentrated to a concentration of about 25% and is carried to its very high vacuum crystallizer - 10 Torr with the help of a high pressure steam jet ejector system. Due to this high vacuum, the liquor begins to boil until the temperature reaches 10 - 12 ℃. At this temperature, the salt begins to crystallize.

The axial flow pump is used for liquor circulation to ensure that the crystal size is uniform and there is no local accumulation of crystals. The slurry is pumped to a hydraulic extraction / pusher centrifuge for separation from colored mother liquor, or salt brought back to feed or solar pond.

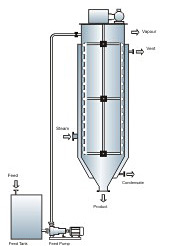

Thickener agitated film dryer

The thickener from the evaporated feed is refused to be delivered by the pump product. The thickener is in a jacketed container of jacket steam and a thin film on the wall of the thickener. The feed is evenly distributed on the outer and inner walls of the thickener with distribution mechanism. When it comes into contact with steam, the water evaporates and the product thickens.

Then, the thickened product is sent to where the filtered sludge can be brought back from the bottom to the concentrated mother liquor for recycling.

For viscous liquids, the agitated film dryer is set where the evaporation surface is continuously wiped off by the agitator.

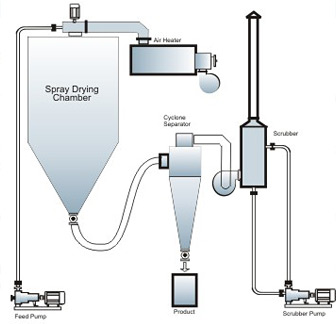

Spray dryer

Spray dryer is a continuous method for drying solution, slurry and slurry in the shortest possible time. Since the liquid is atomized into a small droplet in the chamber through which the electric current passing through the hot air, the drying is fast.

Atomization produces a very large surface area or heat and mass transfer. So drying is very fast. The hot air in contact with the droplet increases its temperature up to the ambient wet bulb temperature of the air.

The characteristics of the spray drying device are applicable to the following applications:

Continuous production

High throughput

Heat sensitive materials

Fully enclosed operation

Ensure purity

Depending on the application, it can have variations in the drying circuit and provide a tailored system to meet the purpose.