Description

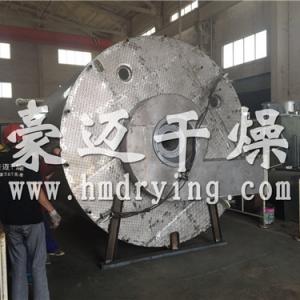

Flash dryer for lithium iron phosphate

Key words: lithium iron phosphate dryer, lithium iron phosphate flash dryer, lithium iron phosphate special flash dryer, battery material dryer, lithium iron phosphate drying equipment

Classification: Battery engineering industry

Case summary: the flash dryer for lithium iron phosphate is a new type of high efficiency fluidization drying equipment developed by Haomai drying company to overcome the low efficiency and high consumption of static drying. Our company has been committed to the drying industry for many years, and the drying technology of battery materials (lithium iron phosphate, ternary materials, etc.) has been mature, and has reached contract online consultation with many enterprises at home and abroad

With the rapid development of new energy vehicle industry, the proportion of global power battery has increased to 28.26% in 2015, becoming an important part of lithium battery. The proportion of power battery in China also increased from 19.38% in 2014 to 36.07% in 2015. In 2015, the global output of lithium-ion batteries reached 100.75gwh, with a year-on-year increase of 39.45%. From 2005 to 2015, the global lithium battery market scale increased from US $5.6 billion to US $22.1 billion, with an annual compound growth rate of 14.7%; it is estimated that the global lithium battery market will reach US $36.3 billion in 2020, and will continue to maintain a high level. Supported by the rapid development of power type lithium batteries, lithium iron phosphate and ternary materials are developing rapidly. As a new and new material in lithium battery industry, lithium iron phosphate develops in the forefront of lithium battery industry by virtue of its high voltage, large capacity, high energy density, long cycle life, small self discharge rate, no memory effect and green environmental protection. According to the relevant characteristics of battery material LiFePO4, the special drying equipment for battery material LiFePO4 developed by Haomai drying should also be shipped out.

Flash dryer for lithium iron phosphate

Lithium iron phosphate flash dryer is a new type of high efficiency fluidized drying equipment developed by our company to overcome the low efficiency and high consumption of static drying. In the design process, the machine fully combines the characteristics of air flow drying and other common fluid drying, makes the whole machine have reasonable process structure and superior performance, and truly realizes the goal of low consumption and high efficiency of fluidized drying.

Structural features and working principle of LiFePO4 dryer:

(1) The bottom of the LiFePO4 dryer is designed as a conical section to establish the velocity gradient of air, which gradually slows down from the bottom to the top, and then forms a certain axial velocity. Under the dual action of rotating air flow and stirring crushing, the gas-solid contact of large particles at the bottom is promoted and drying is accelerated.

(2) The hot air rotates from the annular bottom gap to the bottom of the dryer at high speed. The bottom gap is set on the top of the inverted cone of the gas collecting chamber, and the mixing blade can extend to the bottom of the gas collecting chamber to prevent the rabbit materials from entering the gas collecting chamber and sealing the air inlet annular gap to form a dead angle.

(3) The outer wall of the inner chamber of the gas collecting chamber is a spiral line, which gradually becomes smaller due to the cut-off of the inner chamber, which promotes the hot air to rotate and enter along the annular bottom gap to eliminate the dead corner at the bottom. The effect is the same.

(4) The grading ring can be used to control the size of finished material particles.

(5) The double screw feeding mode is adopted to make the paste and filter cake materials with high viscosity enter into the dryer evenly, and at the same time, it plays a certain role in crushing the larger particles.

(6) A variety of feeding devices for selection, continuous and stable feeding, no bridging phenomenon in the process.

(7) A special cooling device is set at the bottom of the dryer to avoid the deterioration of materials in the high temperature area at the bottom.

(8) Special air pressure sealing device and bearing cooling device can effectively prolong the service life of transmission part.

As a new type of lithium ion battery electrode material, lithium iron phosphate has the characteristics of large discharge capacity, low price, non-toxic, and does not cause environmental pollution. At present, all countries put the battery industry in an important position in the national development strategy. Lithium iron phosphate battery is a new type of lithium battery with high promotion value, and is one of the core products for the future development of battery industry. The lithium iron phosphate dryer developed by Changzhou Haomai drying Engineering Co., Ltd. is a good choice for you with high efficiency, energy saving, large output and good product quality.

Our company has been committed to the drying industry for many years, and the drying technology of battery materials (lithium iron phosphate, ternary materials, etc.) has been mature. We have reached contracts with many enterprises at home and abroad. We welcome customers to inquire!

Key words: lithium iron phosphate dryer, lithium iron phosphate flash dryer, lithium iron phosphate special flash dryer, battery material dryer, lithium iron phosphate drying equipment

Classification: Battery engineering industry

Case summary: the flash dryer for lithium iron phosphate is a new type of high efficiency fluidization drying equipment developed by Haomai drying company to overcome the low efficiency and high consumption of static drying. Our company has been committed to the drying industry for many years, and the drying technology of battery materials (lithium iron phosphate, ternary materials, etc.) has been mature, and has reached contract online consultation with many enterprises at home and abroad

With the rapid development of new energy vehicle industry, the proportion of global power battery has increased to 28.26% in 2015, becoming an important part of lithium battery. The proportion of power battery in China also increased from 19.38% in 2014 to 36.07% in 2015. In 2015, the global output of lithium-ion batteries reached 100.75gwh, with a year-on-year increase of 39.45%. From 2005 to 2015, the global lithium battery market scale increased from US $5.6 billion to US $22.1 billion, with an annual compound growth rate of 14.7%; it is estimated that the global lithium battery market will reach US $36.3 billion in 2020, and will continue to maintain a high level. Supported by the rapid development of power type lithium batteries, lithium iron phosphate and ternary materials are developing rapidly. As a new and new material in lithium battery industry, lithium iron phosphate develops in the forefront of lithium battery industry by virtue of its high voltage, large capacity, high energy density, long cycle life, small self discharge rate, no memory effect and green environmental protection. According to the relevant characteristics of battery material LiFePO4, the special drying equipment for battery material LiFePO4 developed by Haomai drying should also be shipped out.

Flash dryer for lithium iron phosphate

Lithium iron phosphate flash dryer is a new type of high efficiency fluidized drying equipment developed by our company to overcome the low efficiency and high consumption of static drying. In the design process, the machine fully combines the characteristics of air flow drying and other common fluid drying, makes the whole machine have reasonable process structure and superior performance, and truly realizes the goal of low consumption and high efficiency of fluidized drying.

Structural features and working principle of LiFePO4 dryer:

(1) The bottom of the LiFePO4 dryer is designed as a conical section to establish the velocity gradient of air, which gradually slows down from the bottom to the top, and then forms a certain axial velocity. Under the dual action of rotating air flow and stirring crushing, the gas-solid contact of large particles at the bottom is promoted and drying is accelerated.

(2) The hot air rotates from the annular bottom gap to the bottom of the dryer at high speed. The bottom gap is set on the top of the inverted cone of the gas collecting chamber, and the mixing blade can extend to the bottom of the gas collecting chamber to prevent the rabbit materials from entering the gas collecting chamber and sealing the air inlet annular gap to form a dead angle.

(3) The outer wall of the inner chamber of the gas collecting chamber is a spiral line, which gradually becomes smaller due to the cut-off of the inner chamber, which promotes the hot air to rotate and enter along the annular bottom gap to eliminate the dead corner at the bottom. The effect is the same.

(4) The grading ring can be used to control the size of finished material particles.

(5) The double screw feeding mode is adopted to make the paste and filter cake materials with high viscosity enter into the dryer evenly, and at the same time, it plays a certain role in crushing the larger particles.

(6) A variety of feeding devices for selection, continuous and stable feeding, no bridging phenomenon in the process.

(7) A special cooling device is set at the bottom of the dryer to avoid the deterioration of materials in the high temperature area at the bottom.

(8) Special air pressure sealing device and bearing cooling device can effectively prolong the service life of transmission part.

As a new type of lithium ion battery electrode material, lithium iron phosphate has the characteristics of large discharge capacity, low price, non-toxic, and does not cause environmental pollution. At present, all countries put the battery industry in an important position in the national development strategy. Lithium iron phosphate battery is a new type of lithium battery with high promotion value, and is one of the core products for the future development of battery industry. The lithium iron phosphate dryer developed by Changzhou Haomai drying Engineering Co., Ltd. is a good choice for you with high efficiency, energy saving, large output and good product quality.

Our company has been committed to the drying industry for many years, and the drying technology of battery materials (lithium iron phosphate, ternary materials, etc.) has been mature. We have reached contracts with many enterprises at home and abroad. We welcome customers to inquire!