Description

Key words: burning rod drying burning rod belt dryer drying cow dung through flow belt dryer

Classification: agriculture and forestry industry

Case overview: DW series belt dryer is the first single-layer through flow belt series products in China in 1991. It has been successfully used in the drying of dehydrated vegetables, Chinese herbal pieces, fried food, shrimp sticks, washed wool, porcelain powder, ore and other materials. Online consultation

Requirements for material drying:

Fuel rod drying

Material parameters:

Name: fuel rod (mixture of cow dung and sawdust)

Size: 40mm diameter, 100mm length

Monomer weight: ≈ 150g

Moisture content before drying: 40%

Moisture content after drying: 15%

Yield: 10000kg / h

2、 Drying equipment selection and main technical parameters:

DW cross flow belt dryer (heated by direct fired hot blast stove)

The width of the main dryer is 3000mm

Equipment area (length × width × height) 34000 × 3000 × 2520

Installed power 56.5kw/h

Circulating fan 4-72-6c-2.2kw 15 sets

Dehumidification fan 4-72-6c-2.2kw 3 sets

Speed regulating motor bwde-185-5.5kw 1 set

3、 Equipment selection: due to the need of continuous production and ensuring the integrity of products, the materials in the production process should be kept in a static state to reduce unnecessary disturbance in the production process. The equipment can be single-layer DW series belt dryer. If the production site is not enough, the multi-layer DW belt dryer can be used to reduce the floor area of the equipment.

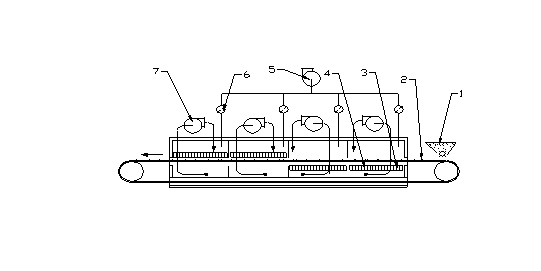

4、 Design Description: The working principle of the equipment is shown in Figure 1. The dryer is divided into several units, and the hot air temperature of each unit can be adjusted separately. The hot air circulation mode can be upward ventilation, downward ventilation or composite ventilation. Generally, the combined ventilation mode of up and down is adopted. Due to the large difference in drying characteristics of various materials, the selection of equipment should be determined through consultation with designers, so that a reasonable combination of ventilation and drying temperature curve can be selected. The exhaust gas emission of this kind of equipment is led out by each unit, and a certain amount of waste gas is discharged by a special dehumidification fan. Each unit is controlled by a regulating valve to facilitate the control of the dry atmosphere in the equipment. In addition, the temperature control of each unit, the control of feeding amount and the adjustment of the running speed of the mesh belt can obtain a good use effect. The design of such equipment accounts for 10% - 17% of the total gas circulation. When the characteristics of materials are different, the equipment selection has great changes. The performance and specifications of DW series are shown in the attached table.

5、 Theoretical calculation:

1. Calculation of water evaporation

Suppose that the dry feed rate is G1 and the moisture content of wet material is x1

The product volume is G2, and the moisture content of the product is x2

The evaporation water volume is w

According to the same amount of dry material before and after drying, then:

(1-X1)G1=(1-X2)G2 ①

W= G 1-G2 ②

1-X2

Let G1 = -- G2 ③

1-X1

1-X2 X1-X2

③ Substituting the formula into ② w = - g2-g2 = - - G2 ④

1-X1 1-X1

Known X1 = 40% (wet material ^ high water content) x2 = 15%

G2=10000㎏/h

1-15%

Substituting into ① G1 = - × 10000 = 14167 / h

1-40%

W = 14167kg / h (feeding amount) - 10000kg / h (product quantity) = 4167kg / h

Classification: agriculture and forestry industry

Case overview: DW series belt dryer is the first single-layer through flow belt series products in China in 1991. It has been successfully used in the drying of dehydrated vegetables, Chinese herbal pieces, fried food, shrimp sticks, washed wool, porcelain powder, ore and other materials. Online consultation

Requirements for material drying:

Fuel rod drying

Material parameters:

Name: fuel rod (mixture of cow dung and sawdust)

Size: 40mm diameter, 100mm length

Monomer weight: ≈ 150g

Moisture content before drying: 40%

Moisture content after drying: 15%

Yield: 10000kg / h

2、 Drying equipment selection and main technical parameters:

DW cross flow belt dryer (heated by direct fired hot blast stove)

The width of the main dryer is 3000mm

Equipment area (length × width × height) 34000 × 3000 × 2520

Installed power 56.5kw/h

Circulating fan 4-72-6c-2.2kw 15 sets

Dehumidification fan 4-72-6c-2.2kw 3 sets

Speed regulating motor bwde-185-5.5kw 1 set

3、 Equipment selection: due to the need of continuous production and ensuring the integrity of products, the materials in the production process should be kept in a static state to reduce unnecessary disturbance in the production process. The equipment can be single-layer DW series belt dryer. If the production site is not enough, the multi-layer DW belt dryer can be used to reduce the floor area of the equipment.

4、 Design Description: The working principle of the equipment is shown in Figure 1. The dryer is divided into several units, and the hot air temperature of each unit can be adjusted separately. The hot air circulation mode can be upward ventilation, downward ventilation or composite ventilation. Generally, the combined ventilation mode of up and down is adopted. Due to the large difference in drying characteristics of various materials, the selection of equipment should be determined through consultation with designers, so that a reasonable combination of ventilation and drying temperature curve can be selected. The exhaust gas emission of this kind of equipment is led out by each unit, and a certain amount of waste gas is discharged by a special dehumidification fan. Each unit is controlled by a regulating valve to facilitate the control of the dry atmosphere in the equipment. In addition, the temperature control of each unit, the control of feeding amount and the adjustment of the running speed of the mesh belt can obtain a good use effect. The design of such equipment accounts for 10% - 17% of the total gas circulation. When the characteristics of materials are different, the equipment selection has great changes. The performance and specifications of DW series are shown in the attached table.

5、 Theoretical calculation:

1. Calculation of water evaporation

Suppose that the dry feed rate is G1 and the moisture content of wet material is x1

The product volume is G2, and the moisture content of the product is x2

The evaporation water volume is w

According to the same amount of dry material before and after drying, then:

(1-X1)G1=(1-X2)G2 ①

W= G 1-G2 ②

1-X2

Let G1 = -- G2 ③

1-X1

1-X2 X1-X2

③ Substituting the formula into ② w = - g2-g2 = - - G2 ④

1-X1 1-X1

Known X1 = 40% (wet material ^ high water content) x2 = 15%

G2=10000㎏/h

1-15%

Substituting into ① G1 = - × 10000 = 14167 / h

1-40%

W = 14167kg / h (feeding amount) - 10000kg / h (product quantity) = 4167kg / h

6、 Process flow chart or picture (Fig. 1)

1. Feeder 2. Conveyor belt 3. Heater 4. Distributor 5. Dehumidification fan 6. Regulating valve 7. Circulating fan