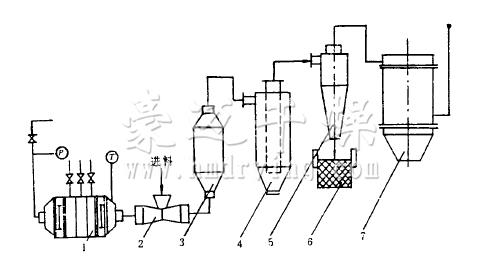

Technological process of cyclone air dryer

Cyclone air dryer is a kind of equipment which uses fluidization and tube wall heat transfer principle to dry materials. The airflow carries the material particles from the tangential direction into the cyclone drying chamber and rotates along the hot wall. The material entering the drying chamber is in the state of suspension and rotation, so the relative velocity of gas-solid phase is very large even at low Reynolds number. In addition, as a result of rotating motion, the particles are continuously crushed, which also increases the contact surface between gas and solid, and strengthens the drying process. The dryer has the advantages of simple structure and small volume. It is especially suitable for heat sensitive granular materials with strong hydrophobicity and no fear of crushing. At present, most of them are used in pharmaceutical industry. It is not suitable for materials with high moisture content, high viscosity, low melting point, easy sublimation, explosion and electrostatic effect.The drying chamber of the cyclone dryer has a diameter of 300-500 mm and a diameter of 900 mm. It is usually used for the first stage cyclone air drying, but it is also used for the two-stage series drying, or the combination of cyclone and straight pipe air drying. The structure of cyclone drying chamber is mostly cylindrical, but it also has conical structure. The conical drying chamber can make the rotation speed of material particles from small to large, which can achieve the purpose of strengthening drying.

The following is the flow chart of oxytetracycline drying in a pharmaceutical factory. Oxytetracycline is manually added into the venturi tube feeder. The compressed air with a gauge pressure of 29.4 kPa is heated to 140-150 ℃ by a steam heater. The wet material is blown into the expansion tank and then dried in a cyclone dryer. The gas-solid mixture enters the cyclone separator to separate the products, and the products screened by the particle screening machine are packaged. The tail gas is filtered by bag filter and then vented.

1 - air heater 2 - feeder 3 - expansion tank 4 - cyclone dryer 5 - cyclone separator 6 - swing granulator 7 - bag filter

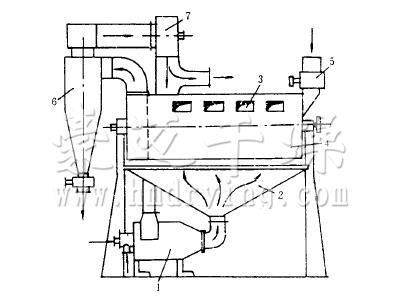

Another type of cyclone dryer, namely horizontal cyclone dryer. The dry medium with pressure from the hot blast stove enters the air distribution chamber first, and then enters the cyclone drying chamber through the tangential direction of the nozzle, so that the air flow forms a rotary motion. The material is sent to the center of the dryer by the feeder, that is, it is entrained by the air flow and moves along the wall of the dryer in a spiral line. After that, the waste gas is separated from the product in the cyclone separator. The waste gas is discharged into the atmosphere by the fan, and part of the waste gas is returned to the heating furnace to be used as circulating gas.

1 - hot blast stove 2 - air distribution chamber 3 - nozzle 4 - cyclone drying chamber 5 - feeder 6 - cyclone separator 7 - Fan

This kind of dryer is especially suitable for materials with low diffusion resistance, and can also be used as the first stage of combined dryer, so as to strengthen the drying process and improve the efficiency.