Description

Classification: Battery engineering industry

Case overview: in this era of rapid development of lithium battery industry, Haomai drying developed a new ternary material dryer for battery materials with high quality, high thermal efficiency and small floor area, which can meet the needs of major battery material manufacturers. Our company has studied the drying technology of battery materials such as lithium carbonate, lithium iron phosphate, nickel cobalt hydroxide, cobalt tetraoxide, nickel cobalt lithium manganate, etc. Interested customers welcome

Since the Ministry of Finance and other four ministries and commissions issued the notice on adjusting the financial subsidy policy for the promotion and application of new energy vehicles (Aiji, net value, information) on December 30, 2016, the R & D and production of high nickel ternary battery has been on a "prairie fire". The capacity expansion of large battery enterprises such as catl, GuoXuan and Yinlong has also increased the demand for lithium battery equipment. According to the big data tracking data of lithium power, in 2017, the new capacity of power lithium battery industry will exceed 30gwh, and the corresponding equipment market size will exceed 15 billion yuan based on the average 1GWh corresponding to the equipment demand of 500-600 million yuan. In 2017, the upgrading and upgrading of power battery system will appear in the field of ternary lithium battery. In this era of rapid development of lithium battery industry, Haomai drying developed a new ternary material dryer for battery materials with high quality, high thermal efficiency and small floor area, which can meet the needs of major battery material manufacturers.

Ternary material dryer:

The traditional drying system of ternary materials adopts the hot air circulation oven. The ternary materials are heated and dried inside the oven until the drying is qualified, and the drying of a batch is completed by manual unloading. Although the cost of the equipment is low, the labor intensity of the workers is large, the area is large, the drying time is long, and the working environment is poor. According to the characteristics of ternary materials, our company's technicians have developed a new type of special disc dryer for ternary materials.

Brief introduction of disc continuous dryer for ternary materials:

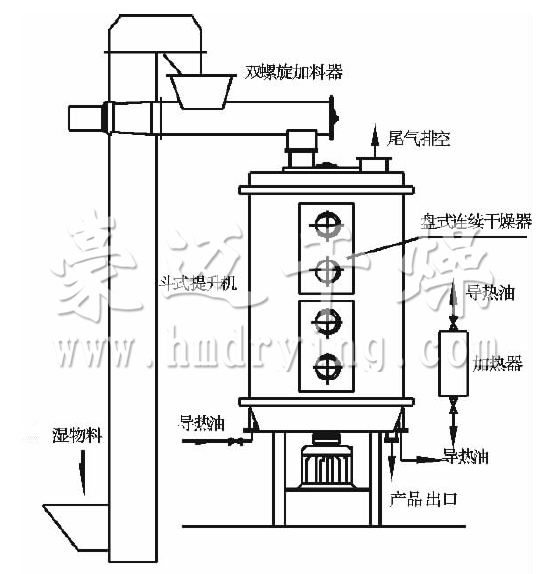

The ternary material drying system is a new type of conductive drying equipment. Its configuration is simple, it does not need cyclone dust collector which must be equipped for air drying, and does not use hot air as heating medium. Therefore, the product loss caused by poor separation of hot air and dust with tail gas will not occur. The disc continuous dryer is composed of a drying plate, a rake arm, a number of rake leaves installed on the rake arm, a main shaft, a transmission device, a shell, etc. the hollow drying plate is filled with heating medium. The drying plate is arranged in a horizontal layer in the dryer. The drying plate is stationary, and the material is driven by the rake blade on the disc surface. In the process of movement, the material is heated by the drying plate to carry out heat and mass transfer to complete the drying operation. The whole drying process is closed. According to the output, property, initial and final moisture content of the material to be dried, the number of drying tray layers (drying area) is determined.

The process of drying ternary materials with disc continuous dryer is as follows

Features of ternary battery material dryer:

1. Continuous operation, high thermal efficiency: the disc continuous dryer is dry by conduction heat transfer. In the drying process, only a small amount of air is introduced into the dryer, and the tail gas carrying capacity is very small, so its thermal efficiency can reach more than 65%.

2. Low power consumption and low noise: due to the thin material layer and low spindle speed, the power consumption of the whole drying device is only 1 / 5 ~ 1 / 7 of the power consumption of the convective heat transfer device, and the noise is very low.

3. The material is heated evenly and the drying time is short: in the drying process, the material rolls forward along the Archimedean spiral track in the drying plate, and the material walks 5 times of the drying disk radius, and falls layer by layer, so the time for the material to contact the heating plate surface is basically the same, and the heating is very uniform.

4. Small material loss and good environmental protection: during the drying process, the materials enter and exit from the top, the material distribution is also wet and dry at the bottom, and the drying tail gas flow rate is very low (about 0.1m/s), so the material dust is difficult to float to the top of the equipment, and it will not be carried away by the tail gas, which will not only not damage the materials, but also not pollute the environment.

5. Equipment closed continuous operation, low labor intensity of workers.

6. Easy installation, small floor area: due to the dry tray layout and vertical installation, even if the drying area is large, the floor area is also very small.

7. Energy saving: the drying medium can use the waste heat steam produced by the boiler, thus saving a lot of coal.

8. The product quality is stable: due to the continuous drying method of disc, the material is heated evenly, and the product quality can be guaranteed.

The company has many years of experience in the research and sales of battery drying machine, and has been engaged in the research and sales of battery drying equipment. In addition, our company has studied the drying technology of battery materials such as lithium carbonate, lithium iron phosphate, nickel cobalt hydroxide, cobalt tetroxide, nickel cobalt lithium manganate, etc