Description

Key words: konjac drying machine, konjac dryer, konjac belt dryer

Classification: Food Engineering Industry

Case summary: konjac drying is not only to remove water, but also to prevent oxidation browning of materials during drying. This problem is very important in the production of konjac flour. The quality of konjac flour has a great influence on the price. On the basis of the original DW type belt dryer drying konjac strips, according to the process requirements, the DWP jet airflow belt dryer was withdrawn

Project Overview:

The moisture content of konjac fresh bulb is 80% ~ 85%, and the skin is thin and the flesh is brittle. It is easy to be injured and rotten. After digging and collecting, it should be sent to the baking plant for dehydration as soon as possible, so as to maintain the quality, become the commodity raw material, and also be convenient for packaging and long-distance sales.

Sand, hair and other debris, keep taro clean.

The processing procedure of taro chips is as follows: fresh konjac bulbs → removing buds and roots → cleaning and peeling → slicing or blocking → color protection → drying → inspection → packaging → finished products.

Konjac drying machine:

This problem is very important in the production of konjac flour. The quality of konjac flour has a great influence on the price. On the basis of the original DW type belt dryer drying konjac strips, according to the process requirements, the DWP jet airflow belt dryer was withdrawn. Because of the big difference between the drying process parameters and other equipment, it was used as a special type.

Special konjac dryer features:

1. Most of the time in the drying process, the material temperature is not more than 55 ℃, and the dried konjac strips are white and bright.

2. The instantaneous hot air treatment in the early stage of drying can rapidly remove most of the water on the surface of the material and reduce the enzyme activity, thus preventing oxidative browning during drying.

3. In the later stage of drying, when the moisture content of the material is about 20%, the material temperature is gradually heated to 80-85 ℃ for discharging, so as to achieve the effect of enzyme killing and not make the magic taro strip become translucent.

4. The drying speed is fast, konjac is cut into 8mm square strips, and the drying time is about 100 minutes.

For the drying of konjac, it is the key to ensure the yield and quality to adopt the treatment of large air volume and high-speed jet airflow.

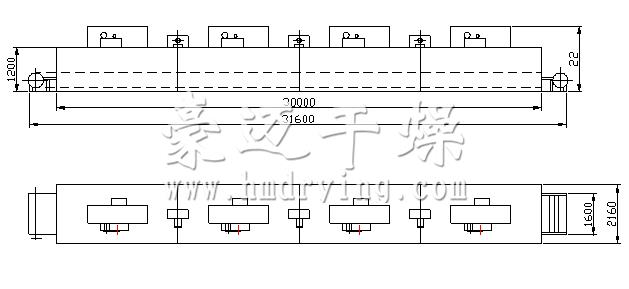

Technical parameters of 100kg / h konjac special dryer:

The net width is 1.6m, the length of drying section is 30m, and the total installed power is 50KW

Steam consumption of matching steam heater is 1.5t/h

Supporting coal-fired hot blast stove 120kcal / h

Fuel consumption of matching oil fired hot blast stove is 75kg / h

Classification: Food Engineering Industry

Case summary: konjac drying is not only to remove water, but also to prevent oxidation browning of materials during drying. This problem is very important in the production of konjac flour. The quality of konjac flour has a great influence on the price. On the basis of the original DW type belt dryer drying konjac strips, according to the process requirements, the DWP jet airflow belt dryer was withdrawn

Project Overview:

The moisture content of konjac fresh bulb is 80% ~ 85%, and the skin is thin and the flesh is brittle. It is easy to be injured and rotten. After digging and collecting, it should be sent to the baking plant for dehydration as soon as possible, so as to maintain the quality, become the commodity raw material, and also be convenient for packaging and long-distance sales.

Sand, hair and other debris, keep taro clean.

The processing procedure of taro chips is as follows: fresh konjac bulbs → removing buds and roots → cleaning and peeling → slicing or blocking → color protection → drying → inspection → packaging → finished products.

Konjac drying machine:

This problem is very important in the production of konjac flour. The quality of konjac flour has a great influence on the price. On the basis of the original DW type belt dryer drying konjac strips, according to the process requirements, the DWP jet airflow belt dryer was withdrawn. Because of the big difference between the drying process parameters and other equipment, it was used as a special type.

Special konjac dryer features:

1. Most of the time in the drying process, the material temperature is not more than 55 ℃, and the dried konjac strips are white and bright.

2. The instantaneous hot air treatment in the early stage of drying can rapidly remove most of the water on the surface of the material and reduce the enzyme activity, thus preventing oxidative browning during drying.

3. In the later stage of drying, when the moisture content of the material is about 20%, the material temperature is gradually heated to 80-85 ℃ for discharging, so as to achieve the effect of enzyme killing and not make the magic taro strip become translucent.

4. The drying speed is fast, konjac is cut into 8mm square strips, and the drying time is about 100 minutes.

For the drying of konjac, it is the key to ensure the yield and quality to adopt the treatment of large air volume and high-speed jet airflow.

Technical parameters of 100kg / h konjac special dryer:

The net width is 1.6m, the length of drying section is 30m, and the total installed power is 50KW

Steam consumption of matching steam heater is 1.5t/h

Supporting coal-fired hot blast stove 120kcal / h

Fuel consumption of matching oil fired hot blast stove is 75kg / h

Konjac dryer layout (DWP Series)