Description

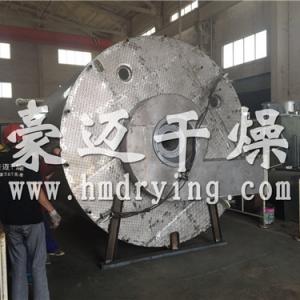

Cobalt tetroxide dryer

Key words: cobaltous oxide disc dryer, battery material dryer, cobalt tetroxide dryer, disc dryer, cobalt tetroxide special disc dryer

Classification: Battery engineering industry

Case overview: Haomai drying has carried out a lot of research and Analysis on cobalt tetroxide and other cathode materials for secondary batteries for many years, and has many years of design and manufacturing experience. It has adopted energy-saving and environmental protection type disc dryer to dry cobalt tetroxide in China. The results show that the product is of high purity, good physical and electrochemical properties, and the continuous drying of the disc dryer has the advantages of small floor space and operation

Cobalt trioxide (Co3O4) is a kind of functional material with special structure, which is mainly used to prepare lithium cobalt oxide as cathode material for lithium-ion batteries, and also widely used in supercapacitors, ceramics, catalysts and other fields. With the rapid development of economy, lithium-ion battery has become the ideal chemical energy with the function of energy efficient conversion and storage. It not only brings great convenience to human beings, but also reduces carbon emissions, optimizes energy structure and realizes sustainable development. With the rapid development of science and technology, the growing mobile phones, digital products and electric vehicles have created a huge space for the development of lithium-ion batteries.

The raw materials of cobalt trioxide used in batteries require very high purity. Over the years, Haomai drying has carried out a lot of research and Analysis on the positive materials of secondary batteries such as cobalt tetroxide, and many years of design and manufacturing experience. In China, energy-saving and environmental protection type disc dryer is used to dry cobalt tetroxide. The cobalt tetroxide powder produced by the special disc continuous dryer has high purity, good physical and electrochemical properties, and the continuous drying of the disc dryer has small occupation area and easy operation. At present, our company's Cobalt trioxide disc dryer technology has reached the domestic level.

Recently, many customers have consulted our company about the technology of battery material dryer. Our company has won the deep trust of customers by virtue of our reputation and quality in the drying industry for many years, as well as the cooperation projects of many domestic lithium battery material manufacturers.

Cobalt trioxide disc dryer

The wet material of cobalt trioxide is continuously added into the first layer disc of the dryer through the feeder. Under the continuous rotation of the rake arm, the wet material falls down layer by layer. The heating medium (water, heat transfer oil, etc.) is filled into the hollow drying disk. The heat and mass transfer process of cobalt tetroxide is completed in the flow process to achieve the purpose of drying. The dried material is discharged from the outlet after cooling.

According to the product performance, drying requirements and processing capacity, a series of measures such as stepless speed regulation of the main shaft, manual adjustment of the disc feeder height, control of the temperature distribution of the heating plates in each layer, and cooling and cooling at the end of the period are adopted for the disc dryer to give full play to its superior performance.