Description

Classification: waste water treatment engineering

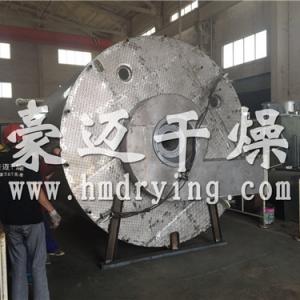

Case summary: what kind of equipment is used to treat salt containing wastewater? Our company specializes in the design and production of waste salt solution and salt wastewater dehydration and drying equipment. In order to further develop the environmental protection market, our company has newly developed a variety of energy-saving and environmental protection drying equipment. This equipment uses the drum scraper dryer, in our company drum scraper design aspect, the scraper blade clamp has the adjustability, guarantees the sufficient rigidity and own density

What kind of equipment is used to treat salt containing wastewater? Our company specializes in the design and production of waste salt solution and salt wastewater dehydration and drying equipment. In order to further develop the environmental protection market, our company has newly developed a variety of energy-saving and environmental protection drying equipment.

Project overview

This equipment is a drum scraper dryer, in our company drum scraper design, scraper blade fixture has adjustable, to ensure sufficient stiffness and its own sealing. In the design of drum body of our company, the cylinder is made of rolled welded structure, which is stress relieved to ensure no thermal deformation in use; at the same time, according to the bad nature of service conditions, the shaft head can adopt the hot sleeve structure, which greatly improves the service life than the welding structure.

Overview of salt wastewater dehydration and drying equipment

Drum scraper dryer is attached to the rotary drum cylinder, the liquid phase material in the way of heat conduction for continuous operation of drying equipment. The material film is formed on the outer wall of the drum rotating at a certain speed by the material liquid and the distributing device, and is heated by the hot drum wall of the heating medium (steam or heat conducting oil) continuously flowing in. The material film is scraped off by a scraper after drying.

The drum scraper dryer is mainly composed of drum (including cylindrical cylinder, end cover, end shaft and bearing), film distributing device (including feed liquid pan), scraping device (including scraper, support frame with pressure regulator, etc.), transmission device (including motor and reducer), inlet and outlet device of heating medium (steam or heat transfer oil) and liquid discharge device.

Characteristics of salty waste water dryer

The roller has high precision and less thermal deformation. After welding, the whole drum is heat stress relieved to reduce the deformation of the cylinder. The surface of the drum is processed by rough turning, fine turning and grinding machine, which has the characteristics of high precision and small deformation in the later stage.

The service life is long, the surface of the roller is plated with hard chromium, and the surface hardness reaches hrc60-65. Make sure that the roller is under the friction of scraper for a long time, the surface wear is small and the service life is long.

The scraper system is reliable and adopts special pneumatic pressing device, which has the characteristics of adjustable and controllable pressing force. It can timely adjust the status of scraper according to the adhesion of materials.

The equipment occupies less land and the investment of workshop is low.

The equipment has low failure rate, reliable operation and simple operation.

Low energy consumption. Due to the adoption of steam conduction heating mode, it has remarkable energy saving effect. The average steam consumption is 1.5 tons per ton of water. Compared with the traditional spray drying operation, energy saving is about 40%.

Installation of drum scraper dryer

The machine is installed according to the general layout, the ground should be flat, the steam pipe inlet should be equipped with pressure gauge and safety valve, and the steam inlet flange should be firmly connected.

Adaptive materials

It is suitable for drying liquid or viscous materials in chemical, dye, pharmaceutical, food, metallurgy and other industries.

maintain

1. After the equipment is used, the residue of drum scraper dryer should be cleaned to keep the whole machine clean.

2. Bearings are often coated with compound calcium grease, drum scraper dryer and worm reducer should be maintained with lubricating oil.

3. The grounding wire of the electric control cabinet and the host machine shall be kept in good condition at any time, and there shall be no leakage.

4. Adjust the tension of the drive chain frequently to make the tension in normal state.

5. Regularly check and verify the pressure gauge, ammeter and voltmeter regularly to make all kinds of instruments and instruments in normal working state.

6. Check the connection of motor, reducer, chain wheel, chain and bearing seat regularly to keep them in a tight state.

debugging

After the machine is installed, the test run should be carried out first

Click the main motor to observe that the rotation direction of the main drum is correct.

Observe whether the main drum and transmission parts rotate flexibly, whether the steam inlet and outlet are connected, and whether the pressure gauge is within the working pressure range.

Start the motor, the main cylinder moves smoothly and steadily. When the temperature is increased, after adding the material, the motor speed and the uniformity of the material on the roller can be adjusted to control the final water content.

Start the auger motor, output the dry finished materials, and adjust the rotation speed of the winch motor according to the amount of dried products.

Technical specification of drum scraper dryer

|

Specifications |

Drum size |

Effective heating area m2 |

Drying capacity |

Steam consumption kg/h |

Motor power kw |

Dimensions mm |

weight kg |

|

HG-600 |

Φ600×800 |

1.12 |

40-70 |

100-175 |

2.2 |

1700×800×1500 |

850 |

|

HG-700 |

Φ700×1000 |

1.65 |

60-90 |

150-225 |

3 |

2100×1000×1800 |

1210 |

|

HG-800 |

Φ800×1200 |

2.26 |

90-130 |

225-325 |

4 |

2500×1100×1980 |

1700 |

|

HG-1000 |

Φ1000×1400 |

3.30 |

130-190 |

325-475 |

5.5 |

2700×1300×2250 |

2100 |

|

HG-1200 |

Φ1200×1500 |

4.24 |

160-250 |

400-625 |

7.5 |

2800×1500×2450 |

2650 |

|

HG-1400 |

Φ1400×1600 |

5.28 |

210-310 |

525-775 |

11 |

3150×1700×2800 |

3220 |

|

HG-1600 |

Φ1600×1800 |

6.79 |

270-400 |

675-1000 |

11 |

3350×1900×3150 |

4350 |

|

HG-1800 |

Φ1800×2000 |

8.48 |

330-500 |

825-1250 |

15 |

3600×2050×3500 |

5100 |

|

HG-1800A |

Φ1800×2500 |

10.60 |

420-630 |

1050-1575 |

18.5 |

4100×2050×3500 |

6150 |