Description

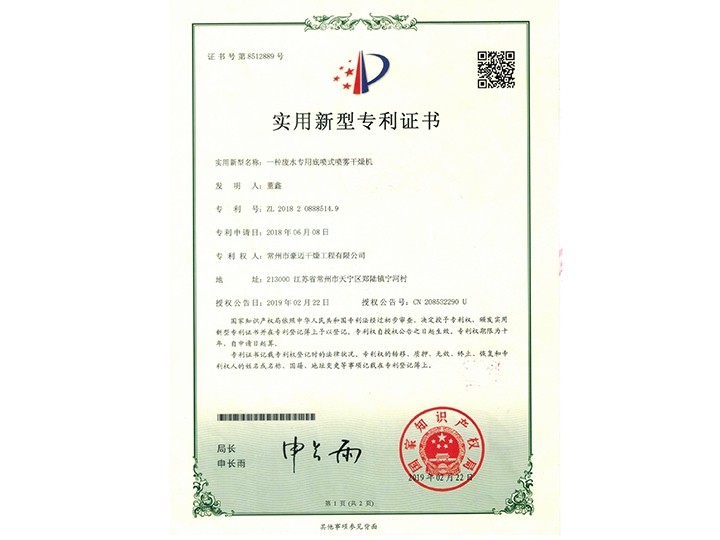

Key words: waste water dryer obtained national patent (Patent No.: ZL 2018 2 0888514.9)

Classification: waste water treatment engineering

Case overview: conventional wastewater treatment methods are mainly divided into physical treatment, chemical treatment and biological treatment. Because the composition of some wastewater is more complex, the conventional treatment method can not completely eliminate the harmful substances in the wastewater. If the harmful substances are completely eliminated, more treatment equipment and large investment are needed. In view of the disadvantages of conventional spray drying machines, our company has developed one.

Conventional wastewater treatment methods are mainly divided into physical treatment, chemical treatment and biological treatment.

Because the composition of some wastewater is more complex, the conventional treatment method can not completely eliminate the harmful substances in the wastewater. If the harmful substances are completely eliminated, more treatment equipment and large investment are needed.

In view of the disadvantages of conventional spray drying machines, our company has developed a new type of spray dryer with bottom injection technology. The dryer belongs to a new type of energy-saving and environmental protection drying equipment.

The new type of bottom spray spray dryer developed by heroic drying has the following advantages:

1. Using heated high temperature air or power plant tail gas (about 400 ℃) as heat source, the utilization rate of heat energy can reach about 70%.

2. changing the dryer to the bottom spray drying method, the volume of the conventional spray dryer equipment is reduced by about 75%, and the investment cost of the equipment is greatly reduced.

3. For the wastewater with complex harmful components, the water can be evaporated at one time, and the volume of the remaining waste residue is reduced by 70-90%, which greatly reduces the volume required for the storage of wastewater, which is convenient for storage and subsequent treatment of waste residue.

4. For the components with single effective components and recycling value in the waste water, after the water drying, the effective components become solid powder, which is convenient for storage, transportation and sales, and has certain economic effect.

5. The dryer belongs to a new type of energy-saving and environmental protection drying equipment, and has been put into the actual industrial production. Users generally reflect that this type of drying equipment has a large treatment capacity and small investment compared with the original wastewater treatment equipment.

Waste water dryer, we are professional!

Classification: waste water treatment engineering

Case overview: conventional wastewater treatment methods are mainly divided into physical treatment, chemical treatment and biological treatment. Because the composition of some wastewater is more complex, the conventional treatment method can not completely eliminate the harmful substances in the wastewater. If the harmful substances are completely eliminated, more treatment equipment and large investment are needed. In view of the disadvantages of conventional spray drying machines, our company has developed one.

Conventional wastewater treatment methods are mainly divided into physical treatment, chemical treatment and biological treatment.

Because the composition of some wastewater is more complex, the conventional treatment method can not completely eliminate the harmful substances in the wastewater. If the harmful substances are completely eliminated, more treatment equipment and large investment are needed.

In view of the disadvantages of conventional spray drying machines, our company has developed a new type of spray dryer with bottom injection technology. The dryer belongs to a new type of energy-saving and environmental protection drying equipment.

The new type of bottom spray spray dryer developed by heroic drying has the following advantages:

1. Using heated high temperature air or power plant tail gas (about 400 ℃) as heat source, the utilization rate of heat energy can reach about 70%.

2. changing the dryer to the bottom spray drying method, the volume of the conventional spray dryer equipment is reduced by about 75%, and the investment cost of the equipment is greatly reduced.

3. For the wastewater with complex harmful components, the water can be evaporated at one time, and the volume of the remaining waste residue is reduced by 70-90%, which greatly reduces the volume required for the storage of wastewater, which is convenient for storage and subsequent treatment of waste residue.

4. For the components with single effective components and recycling value in the waste water, after the water drying, the effective components become solid powder, which is convenient for storage, transportation and sales, and has certain economic effect.

5. The dryer belongs to a new type of energy-saving and environmental protection drying equipment, and has been put into the actual industrial production. Users generally reflect that this type of drying equipment has a large treatment capacity and small investment compared with the original wastewater treatment equipment.

Waste water dryer, we are professional!