Special belt dryer for Chinese Herbal Pieces

According to the drying test data of traditional Chinese medicine pieces, the requirements of temperature, material layer, hot air speed and energy consumption of Chinese herbal pieces are analyzed. The mesh belt dryer is recommended, which covers an area of up to, has large output, good drying effect, energy saving and source saving, and is convenient for equipment maintenance and cleaning.Chinese medicine is a part of Chinese medicine treasure house. Chinese medicine has a history of 5000 years. There were professional "doctors" in the Western Zhou Dynasty. Li Shizhen of the Ming Dynasty spent 27 years compiling the compendium of Materia Medica. Practice has proved that the characteristics and advantages of traditional Chinese medicine are incomparable and irreplaceable. With the development of science and technology, the modernization of drying and extraction of traditional Chinese medicine makes Chinese medicine gradually enter the international market.

According to the drying test data of Chinese herbal pieces, the requirements of temperature, material layer, hot air speed and energy consumption of Chinese herbal pieces are analyzed, and the mesh belt dryer is recommended.

Principle of mesh belt dryer

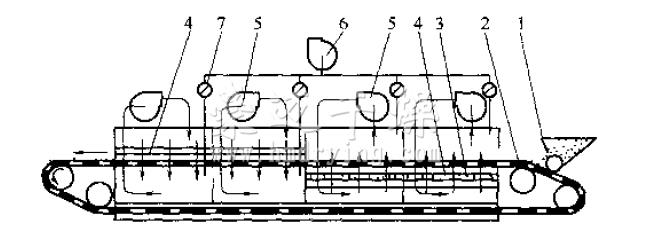

The material in hopper 1 is evenly laid on the mesh belt. The mesh belt is made of 12-60 mesh stainless steel mesh, which is driven by the transmission device and circularly moves in the dryer. The dryer is composed of several units, each of which has an independent hot air circulation. Part of the tail gas is discharged by a special exhaust fan 6, and the amount of exhaust gas discharged from each unit is controlled by a regulating valve 7. In the initial stage of drying, the air from the circulating fan 5 enters the lower part from the side air duct. The air flow is heated up by the heat exchanger and distributed by the distributor 3. The jet flow is blown to the mesh belt, passing through the material and entering the upper part. The hot air passes through the material layer to complete the heat and mass transfer drying process. The wet air is discharged by dehumidification fan 6, and most of it is still circulated by circulation fan 5. In the later stage of drying, the circulating fan 5 blows to the upper heat exchanger 4 and then passes through the material layer to enter the lower part, which can also be partially circulated and partially discharged.

Principle of belt dryer for Chinese Herbal Pieces

1 - feeder 2 - mesh belt 3 - distributor 4 - heat exchanger 5 - circulating fan 6 - dehumidification fan 7 - regulating valve

The characteristics of the machine make the distributor and circulation fan make the hot air flow through the decoction pieces, and the drying effect is good. When the initial moisture content of Chinese herbal pieces is high, the multi-layer mesh belt dryer can be connected in series or made into a single net belt dryer with a longer total length.

The belt dryer for Chinese Herbal Pieces purchased by a pharmaceutical company in Shandong Province has a net width of 1700mm, a drying area of 25m2, a gas consumption of 210kg / h, a production of 116kg / h, and a total installed capacity of 19.5kw. It adopts 24 mesh stainless steel mesh wire. The machine covers an area of up to, with large output, good drying effect, energy-saving and source saving, and convenient equipment maintenance and cleaning.