Description

Key words: Urotropine dryer, urotropine special airflow dryer, urotropine drying equipment, urotropine dryer

Classification: chemical engineering industry

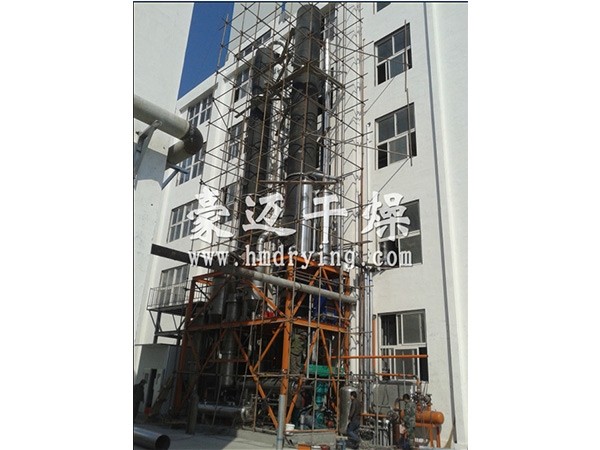

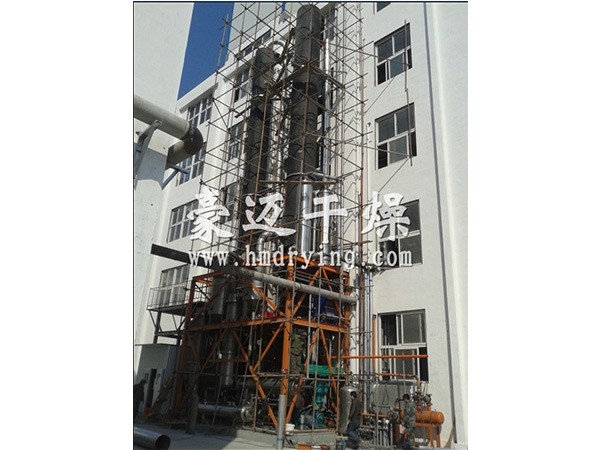

Case summary: the airflow dryer specially designed by Haomai drying company combines pre drying, crushing and final drying together to solve the problem that paste materials cannot be fluidized due to sticking in the drying equipment.

Material description:

The formal name of urotropine is 1,3,5,7-tetraazatricyclo [3.3.1.1] decane, also known as hexamethylenetetramine, tetraazacyclohexane, hexamine, aminoform, hexamethylenetetramine. Urotropine was prepared from formaldehyde and ammonia. It is widely used in chemical industry, medicine, pesticide and other fields.

Process parameters and requirements:

Material name: Urotropine

Moisture Name: water (H2O)

Initial moisture content: ω 1 = 5%

Required moisture content: ω 2 ≤ 0.5% (0.3)

Required treatment capacity: 70t / 24h

Original state of material: loose filter cake (anti caking agent)

Heat source: saturated steam, 0.4MPa, absolute pressure 0.5MPa, saturation temperature 151.85 ℃

Material collection mode: two stage cyclone separator + water washing tower (provided by the demander)

Others: SUS304 (including blower and medium efficiency air filter) is in contact with hot air, and Q235 is used for all flanges and induced draft fans

Heat balance:

Saturated steam temperature t0: 151.85 ℃

Ambient temperature t0: 7.5 ℃ (winter)

Hot air inlet temperature T1: 130 ℃± 5 ℃

Outlet air temperature T2: 70 ℃ (set value)

Wet material temperature θ 1: 7.5 ℃

Material temperature after drying θ 2: 55 ℃

Specific heat of material: 0.62kcal/kg ·℃

Air specific heat: 0.24kcal/kg ·℃

Initial moisture content (WT): 5%

Final moisture content (WT): 0.5%

Water evaporation capacity: ~ 132kg / h

Yield: ~ 2785kg / h

Then: the air consumption is M0 = 12000kg / h

Model of urotropine airflow dryer:

Inlet air temperature: 130 ± 5 ℃

Outlet air temperature: 70 ± 3 ℃ (empirical setting value)

Feed temperature: normal temperature, average 7.5 ℃

Product temperature: 55 ± 5 ℃

Equipment model: a set of jq-500 airflow dryer

Working principle of airflow dryer for Urotropine:

the wet materials are extruded into flake or strip shape by the thrust of spiral plate through the quantitative spiral feeder, and continuously input into the dryer. In the process of falling, it meets with hot air, and part of the water evaporates, so that the viscosity of the material decreases, and the lumpy material continuously falls into the intensifier. It was crushed by a pulverizer and then dried. The powder wet material is suspended in the hot air, and the material is constantly rolling, which increases the heat transfer area, improves the heat transfer coefficient and shortens the drying time. The dried powder continues to rise with the air flow into the cyclone separator for collection, and the tail gas is filtered by the bag filter and then vented. The system combines pre drying, crushing and final drying together to solve the problem that paste materials cannot be fluidized due to sticking in the drying equipment. A kind of

Advantages of Haomai drying JQ enhanced airflow dryer:

At the same time, under the action of the intensifier, the hot air forms turbulent and spiral upward flow, prolongs the residence time of materials, accelerates the flow of materials, and has good heat and mass transfer conditions. Because the material is continuously and stably added into the intensifier by the quantitative feeder, under the action of the pulverizer, the material is quickly crushed and dried by heat and mass transfer process. At the same time, the crushed materials in the strengthening area lose their viscosity and form small pieces and form dilute phase fluidization. The fine materials are entrained out by the air flow at the outlet of the dryer. Therefore, JQ enhanced airflow dryer has dual functions of fluidized bed and air dryer.

Classification: chemical engineering industry

Case summary: the airflow dryer specially designed by Haomai drying company combines pre drying, crushing and final drying together to solve the problem that paste materials cannot be fluidized due to sticking in the drying equipment.

Material description:

The formal name of urotropine is 1,3,5,7-tetraazatricyclo [3.3.1.1] decane, also known as hexamethylenetetramine, tetraazacyclohexane, hexamine, aminoform, hexamethylenetetramine. Urotropine was prepared from formaldehyde and ammonia. It is widely used in chemical industry, medicine, pesticide and other fields.

Process parameters and requirements:

Material name: Urotropine

Moisture Name: water (H2O)

Initial moisture content: ω 1 = 5%

Required moisture content: ω 2 ≤ 0.5% (0.3)

Required treatment capacity: 70t / 24h

Original state of material: loose filter cake (anti caking agent)

Heat source: saturated steam, 0.4MPa, absolute pressure 0.5MPa, saturation temperature 151.85 ℃

Material collection mode: two stage cyclone separator + water washing tower (provided by the demander)

Others: SUS304 (including blower and medium efficiency air filter) is in contact with hot air, and Q235 is used for all flanges and induced draft fans

Heat balance:

Saturated steam temperature t0: 151.85 ℃

Ambient temperature t0: 7.5 ℃ (winter)

Hot air inlet temperature T1: 130 ℃± 5 ℃

Outlet air temperature T2: 70 ℃ (set value)

Wet material temperature θ 1: 7.5 ℃

Material temperature after drying θ 2: 55 ℃

Specific heat of material: 0.62kcal/kg ·℃

Air specific heat: 0.24kcal/kg ·℃

Initial moisture content (WT): 5%

Final moisture content (WT): 0.5%

Water evaporation capacity: ~ 132kg / h

Yield: ~ 2785kg / h

Then: the air consumption is M0 = 12000kg / h

Model of urotropine airflow dryer:

Inlet air temperature: 130 ± 5 ℃

Outlet air temperature: 70 ± 3 ℃ (empirical setting value)

Feed temperature: normal temperature, average 7.5 ℃

Product temperature: 55 ± 5 ℃

Equipment model: a set of jq-500 airflow dryer

Working principle of airflow dryer for Urotropine:

the wet materials are extruded into flake or strip shape by the thrust of spiral plate through the quantitative spiral feeder, and continuously input into the dryer. In the process of falling, it meets with hot air, and part of the water evaporates, so that the viscosity of the material decreases, and the lumpy material continuously falls into the intensifier. It was crushed by a pulverizer and then dried. The powder wet material is suspended in the hot air, and the material is constantly rolling, which increases the heat transfer area, improves the heat transfer coefficient and shortens the drying time. The dried powder continues to rise with the air flow into the cyclone separator for collection, and the tail gas is filtered by the bag filter and then vented. The system combines pre drying, crushing and final drying together to solve the problem that paste materials cannot be fluidized due to sticking in the drying equipment. A kind of

Advantages of Haomai drying JQ enhanced airflow dryer:

At the same time, under the action of the intensifier, the hot air forms turbulent and spiral upward flow, prolongs the residence time of materials, accelerates the flow of materials, and has good heat and mass transfer conditions. Because the material is continuously and stably added into the intensifier by the quantitative feeder, under the action of the pulverizer, the material is quickly crushed and dried by heat and mass transfer process. At the same time, the crushed materials in the strengthening area lose their viscosity and form small pieces and form dilute phase fluidization. The fine materials are entrained out by the air flow at the outlet of the dryer. Therefore, JQ enhanced airflow dryer has dual functions of fluidized bed and air dryer.